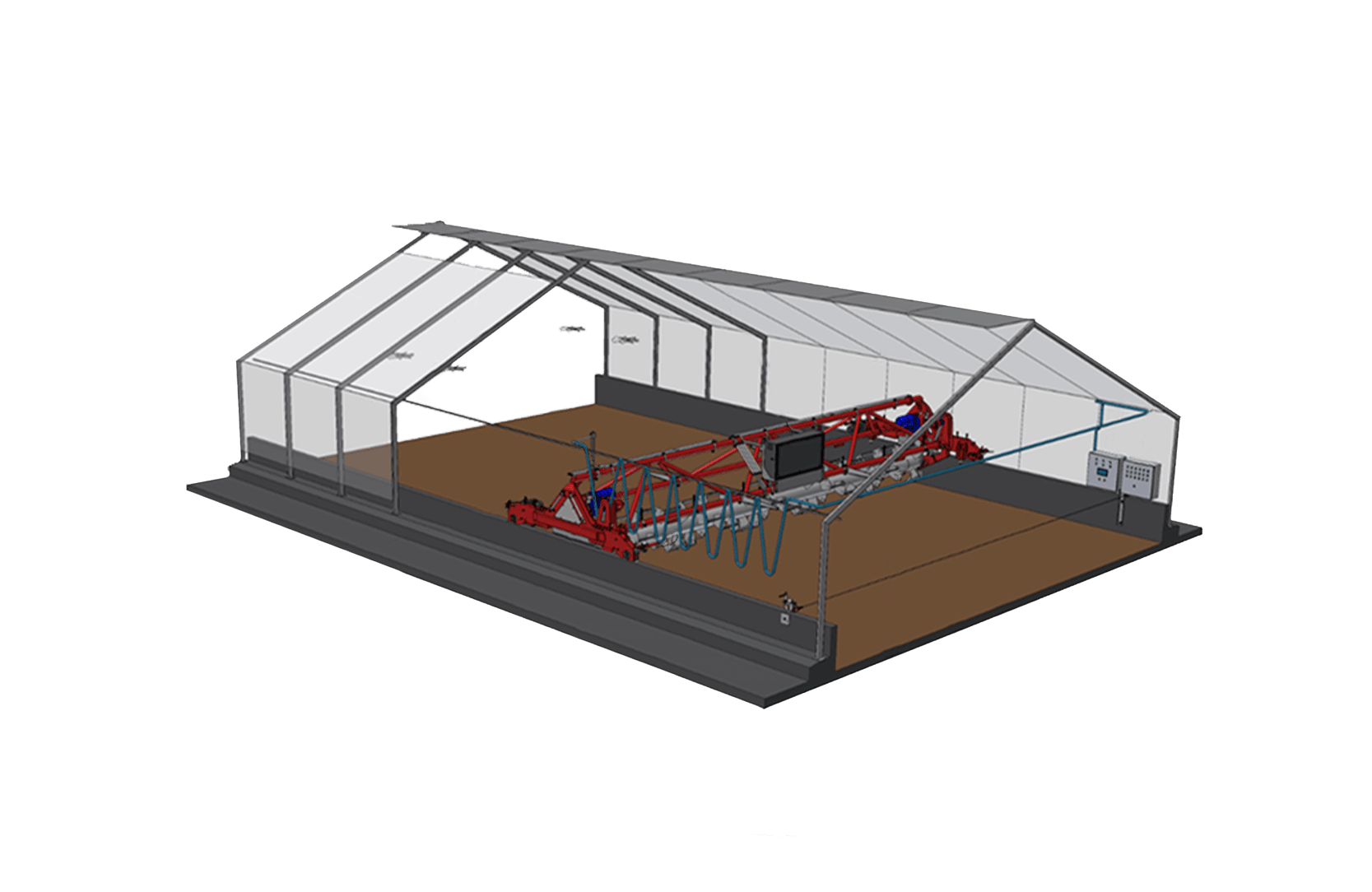

The aim of clear sludge drying is to reduce the volume and moisture content to up to 90 % dry matter, which leads to considerable savings in disposal costs. The high-quality dried sludge can then be used in a variety of ways: for example in agriculture, road construction, phosphorus recovery, as a substitute fuel or for raw material substitution in the cement and clinker industry. The WendeWolf® forms the centrepiece of every solar drying system. As a fully automatic turning and conveying system that covers the entire width of the hall, it ensures uniform, energyefficient and reliable drying of sewage sludge – with minimal labour costs.

The technology of the WendeWolf® is based on decades of practical experience in in-house operation. This expertise stands for maximum operational reliability, continuous development and proven process quality – with over 200 successfully installed systems worldwide.

The WendeWolf® distributes, turns and conveys the sludge fully automatically. The timing of the turning process is precisely aligned to the actual energy input from solar radiation – for maximum drying performance with minimum energy input. A weekly timer programme accurate to the minute enables individual work programmes to be started on a time-controlled basis. All processes can be easily and clearly customised and controlled via a user-friendly control panel.