This process uses organic hollow fibers made of robust HDPE with micropores as the filtration medium to ensure efficient and reliable wastewater treatment.

Our technology is used in various areas, including biological wastewater treatment (MBR) for water reuse, drinking water treatment, retrofitting existing treatment plants, groundwater, surface water, and gray water treatment, landfill leachate treatment, flue gas condensate cleaning in biomass power plants, industrial wastewater treatment, compact household units, disaster response packages, and industrial wastewater treatment. Due to its versatility, the C-MEM™ technology can be flexibly adapted to different needs.

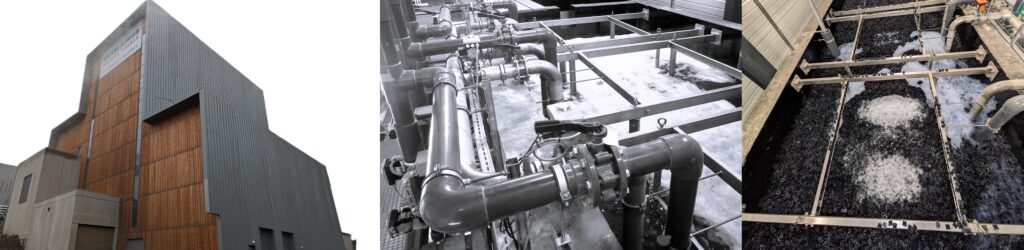

C-MEM™ Functionality

The functionality of the C-MEM™ technology is based on submerged organic hollow fibers with an outer diameter of 0.3 to 0.5 mm, depending on the application area. These fibers are bundled together to achieve a large surface area and high flow rates. In wastewater treatment, C-MEM™ is usually operated as a membrane bioreactor (MBR). The biologically pre-treated raw water is fed through the membrane fibers in the cartridges (outside-in operation). Suction pressure draws the water through the micropores into the interior of the fibers while activated sludge and other suspended solids, bacteria, and viruses are retained. An air scour prevents the membrane from clogging, and cleaning is done through a CIP (Cleaning in Place) process where the membrane’s operating mode is reversed (inside-out operation).