capacity: 58 l/s start-up: 2006 [Vollansicht]

C-FLOC is a process for removing colloid particles from water by flocculation and sedimentation.

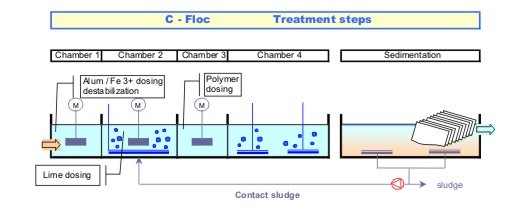

The process takes place in 4 steps, each in an individual chamber and therefore at optimum mixing conditions and ripening periods, whereby the colloids are first transformed into micro-flocs and then into macro-flocks, which can be separated from the water very well.

These 4 process steps are:

- Destabilisation: by adding alum or ferric (III) chloride the charges of the small colloid particles are destabilized, which allows the particles to agglomerate.

- Contact flocculation: by return sludge supply the flocculation process gets optimized and the chemicals applied can be used more efficiently.

- Polymer dosing: by polymer dosing the flock size is increased and settleability gets improved.

- Hydropneumatic flocculation: coarse bubble aeration supports the final flocculation.

After these 4 steps the sludge is separated from the water by sedimentation with lamella separators. One part of the sludge is returned to contact flocculation as return sludge, the remaining surplus sludge gets discharged.

The process can be applied for water treatment as well as for downstream phosphorus removal in wastewater treatment plants.

Advantages of C-FLOC

- The chemicals and flocculants applied can be used more efficiently due to the individual chambers.

- The mixers used in the individual chambers are smaller and therefore need less energy.

- Subsequent process steps such as e.g. filters can be dimensioned more economically.

Unique Features:

We have learned from the deficiencies of other flocculation technologies and have refined these technologies.

The following features prove this and hence clearly speak for C-FLOC:

Separated chambers for separate reactions

hence shorter retention times, less reaction volume, lower consumption of chemicals and flocculation agents, less energy consumption, operation and maintenance cost savings

Circulation of contact sludge

hence full utilization of flocculation agents and better efficiency of the technology, support of flocculation

Most efficient removal of colour and turbidity

hence better effluent quality and healthier drinking water